Arbeitsgruppen

© BVT

© BVT

Smart Bioproduction Grids

Smart Bioproduction Grids comprises the combination of different processes and process steps for a resource and environmental friendly bioproduction.

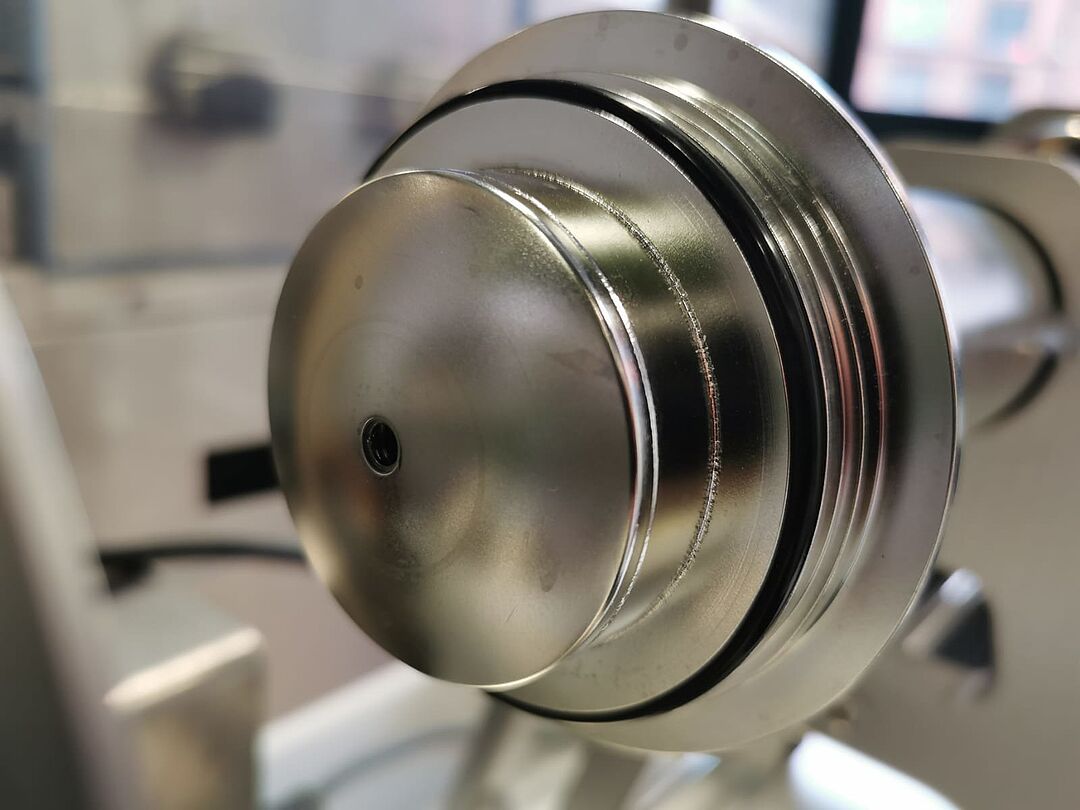

The use of organic residuals for the biotechnological production of food and feet additives, biopolymers and energy are key goals. The differentiation in multiple process steps is crucial when using waste streams. Process coupling and co- or mixed cultivation techniques are used for the production of valuable compounds. Pre-treatment of the feedstock is necessary, when biogenic residuals are used, since it can ensure a reliable process operation. For each process step different conditions in terms of temperature, gas and nutrient availability, pH e.g. are optimal, therefore different reactor designs and bioprocess strategy are applied. Shaken single-use bioreactors are the best option for the cultivation of many shear sensitive stains.

Process operation is often continuously or in fed-batch mode in large bioprocesses. Therefore, scale-down strategies are implemented to investigate scaling effects already in lab-scale. Lifecycle assessment can be used to evaluate the biotechnological processes with respect to their ecological and economical impact.

KIWI Biolab

The KIWI Biolab focuses on automated methods and model-based bioprocess engineering. Our main goal is to find optimal process conditions for biotechnological applications. For this purpose, pipetting robots / liquid handling stations are combined with process models and machine learning approaches. By combining automation and modeling, highly complex tasks can be performed quickly and precisely that would not be possible manually.

The KIWI Biolab is dedicated to a broad spectrum of biotechnological process development from library screening to conditional screening under scale-down conditions. The development and application of mechanistic models represents a large part of the research group. In the context of collaborations, hybrid models and machine learning are increasingly becoming the focus of our work. The developed models are used for process monitoring as well as for process control (model predictive control). In addition to the model-based methods, the HT lab is the heart of this research group. With the establishment of this lab, the KIWI Biolab has acquired great competences in automation, integration of lab equipment and software engineering. This knowledge is contributed to various projects and to the SiLA consortium.

© BVT

© BVT

Process Analytical Technology

Process Analytical Technologies (PAT) methods are of increasing importance for process development and production in the meaning of Quality by Design.

Beside traditional fields of PAT as pharma and chemstry, anaerobic processes as brewing and biogas production are in the focus of the development and application of novel sensors. As morphological characteristics of microbial cultures can be used to observe and control in a wide range of bioprocesses.

Biogas production is still a black box, while the ongoing transmission of energy supply demands a maximum of efficiency and flexibility of the biogas processes in terms of substrate utilization and energy provision. In these mixed cultures, monitoring of characteristics can lead to the knowledge of the cultural composition and process state. However, in large scale bioprocesses, the microbial and process conditions differ inside the reactor, therefore multiposition monitoring is of special interest.

The observation of microbial cells e.g. cell size, viability and vitality should be carried out insitu or online as the cellular reaction might be influenced by the preparation for offline processing.

Our goal is a better integration of processes into closed supply chains and Smart Bioproduction Grids with enhanced monitoring strategies and process control.

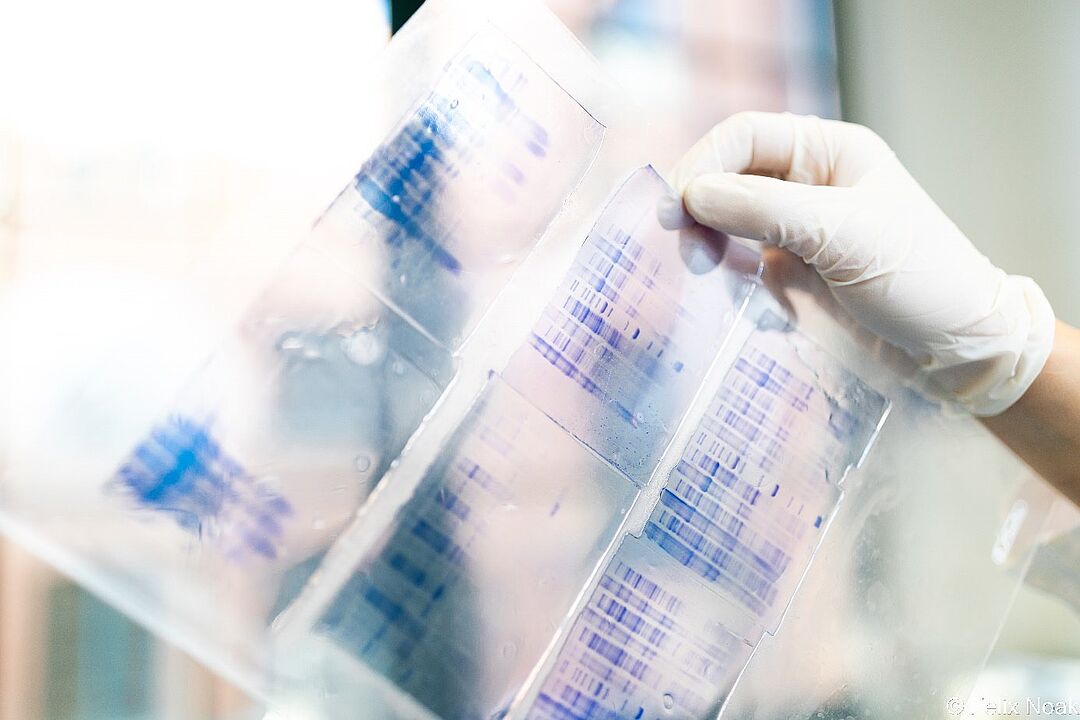

Molecular Biology & Applied Biocatalysis

Our scientific interest is the production of "difficult to express" proteins in Escherichia coli and other prokaryotic hosts. These include multisubunit proteins, superlarge enzyme complexes, metalloproteins or peptides. Optimisation strategies are directed to proper folding of the proteins of interest with a special focus on posttranslational modifications, such as disulfide bond formation.

The current proteins of interest include (i) enyzmes in the nucleoside and nucleotide metabolism for the synthesis of non-natural bioactive compounds and (ii) the synthesis of ribosomal and nonribosomal bioactive peptides and (iii) hydrogenases.

For the selection of the biocatalysts and successful process development we closely cooperate with the other BVT groups. This guarantees a fast and consistent developmental process.